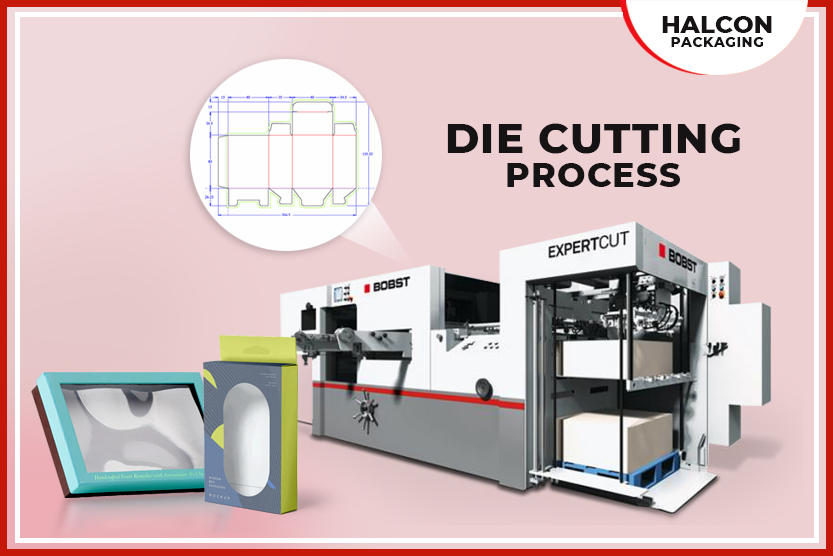

What is Die Cutting? What Is It Importance In The Die Cut Process?

Die cutting is employed in the printing and packaging sector to indicate the cutting down of several shapes using tools or machines. With die-cut, it is possible to specify accurate dimensions and have the tools cut them to the required measurement each time. As you can assume, this accuracy is helpful for item packaging design, where you require to produce a uniform and expert look each time.

What Is Meant By Die Cutting?

Die cutting is a production process where die plates are; personalized through forming, cutting, or shearing to pursuit the required shape, layout, or pattern. Die-cut pressing is used in the custom packaging process to; accurately cut, craft, and print according to particular dimensions and specs, as described in a die-line.

What Are The Die Plates?

Die cuts start with a die plate which is a metal thing that has edged areas for cutting. A die looks like cookie cutters in the state that the metal thing is; designed for, and it will be the identical shape that cuts the packaging material. There are different sets of die plates. For instance, steel-type dies are very razor cut yet are; preserved with synthetic or bubbles for protection.

Steel-type die plates are; produced to cut thicker packaging stock or to; cut a pile of bit-thick packaging material all at once. There are also thinner die plates, which are not sharp and cannot cut highly thick stock. These kinds of die plates are lighter in weight and more comfortable to store, and likewise do not have bubbles or plastic all around them for protection.

What Are Manual and Digital Die Cutting Machinery?

Die-cutting works both manually and digitally through machines. Manual die cutting devices use a crank that is; used to cut the stock. The metal die plates pass through the device’s rollers and use that strength to assist cut the pattern out of the material based on the layout of the die. Manual machines may also have motors that assist to; apply this weight.

Digital die cutting machines or devices are; usually measured by software. They do not need steel die plates, as there is; a knife blade within the device that cuts the pattern. The software is; utilized to choose that template, and it can be; designed via computer, tablet, phone, or indeed a specific cartridge that the device works.

Why is it Known As Die Cutting?

The beginning of the phrase die-cutting originates from the 13 century. From the central word ‘de’, considered to be, from the Latin term “datum” for “delivered”. The root definition of die-cutting is to cast. Back in the 13 century, die plates were; initially used to; cast or mark metal money. It was not till the 18 century that the production of goods of identical size and appearance took off, and this ancient term “die” was utilized to define that it was “designed by devices”. Cut indicates designing a custom style, and die-cutting involves the casting of style or shapes.

The word die cutting was not generally used till the 18th century, while it was; intended as a process for producing more accurate shoe sizes. Since footwear was; made of vellum, the soles had to be; cast by hand, which was a tiresome process that usually led to mistakes and non-accurate size shoes. When the die cutting device was; designed - this meant that shoes can now have regular sizes.

Also Read: What is Varnish? How Varnish Is Used in Printing and Packaging?

Also Read: What is Varnish? How Varnish Is Used in Printing and Packaging?

The Purpose of a Dieline in the Custom Process:

Before you create a die-cut on any printed stock or paper, you will need to first, have a plan of; what requires to be; cast. It is where a die-line arrives in the process. Dielines are part of die-cut plates and are; utilized to describe the style and packaging size before any cutting occurs.

With several styles and shapes possible in the packaging and printing world, if you could imagine it, possibilities are; a custom packaging company can create the stock into any cuttable style. If you still require to create a die-line, browse our example about what a die-line is to study more about how to; create a die plate for your packaging project. Remember, you will require a die-line before you can move to the finishing touches of your boxes like embossing and debossing, matte and gloss lamination, or UV coating.

Ideas for Various Types of Die Cutting Processes:

There are several examples of die-cutting processes. The one utilized for your project will solely depend on your particular requirements and your concept for your goods. Some of the popular approaches, include the following:

- Coining: With coining, round holes are; produced in the stock by adding weight to them. It produces a very complex look in printed packaging.

- Drawing: Drawing draws stock into the machine to a particular length. It is; commonly used for goods that are light and/or extended.

- Blanking: Blanking takes smooth stock and parts it by cutting it from the outer corner, which; lets it look even flatter.

- Broaching: Many rows of “fangs” are used to cast material that the die plates cannot unless cut utilizing the broaching process.

- Forming: Forming occurs if the raw material is; molded on a rounded surface. It is commonly used concurrently with your design to produce tubular parts of your custom box packaging.

There are several other kinds of die-cutting out in both offset and digital printing, yet this will provide you an opinion of the standards most frequently used in customized packaging. Beyond the varieties of die-cutting, there are also many die-cutting services solely depending on your necessities. For example, flatbed die-cutting, also identified as steel rule die-cutting, employs a flatbed cutting press and custom die plates to produce its custom styles or shapes. It is excellent for thicker stock, more comprehensive parts of the packaging, or even short-term production series.

For larger volume manufacturing, there is rotary die-cutting, which uses a round-shaped die to transform flexible stock into custom packaging. It is typical for high-volume production as well as ideas that need precise efficiency. There is also digital die-cutting, which does not use die plates at all. Rather, it utilizes lasers, areas, and tool parts to the crease, score, and cast the material. This kind of die-cutting is; famously used for purposes that require fast turnaround times but still need high levels of accuracy.

Can I Create My Own Steel Dies?

However, you technically can create your die plates by welding several parts together, it is; not suggested. In this example, it is good to; leave the die-cutting as well as the styling and creating of die plates, to the printing and packaging professionals. If you have an; irregular style in mind for your printed box packaging, it is ideal to; let us build the die plates for it, because this way, we can be assured that it will run with our functional machines.

What Are Cutting Pads or Plates?

Cutting plates, also recognized as cutting pads, build a variety of “die-cut sandwiches” of all of the parts and stock required to let your packaging idea into reality. The “sandwich” is a kind of packaging, the layout, and more so that the outcomes come out resembling precisely the way you thought. Consider it as an identical process as placing a cookie cutter through the batter to produce your typical style, which you can then finish. Die cutting is the same process through the application of cutting plates. Over time, these plates require to be; reinstated because they can waste down.

Using Die-Cutting To Create Your Personalized Packaging:

As you can notice, die cutting is a highly adaptable way to; carefully cut, style, and print your boxes so that the effects can be; repeated again and again without a place for mistakes. Not only is die-cutting accurate, but it also enables you a great understanding of liberty with your retail packaging needs. Yet, we know that not everyone is a packaging specialist. Luckily, at Halcon Packaging, we are. We would be pleased to answer any issues you might have about the die-cutting process or how it will operate with your product packaging concept.

If you have a concept in mind yet are not certain how to make it a reality concerning the packaging of your item, do not worry. We have a member of remarkable designers that can transform your imagination for your corrugated boxes, carton boxes, or other branded packaging into a beautiful, eye-grabbing truth. We encourage you to contact us to request a free quote about our box and printing processes as well as our packaging layout choices to help find out the most suitable way forward for your bizarre design.