What To Consider When Using Offset Printing Method?

Here are some things to consider while creating a custom printing job. It's all too simple to forget about them.

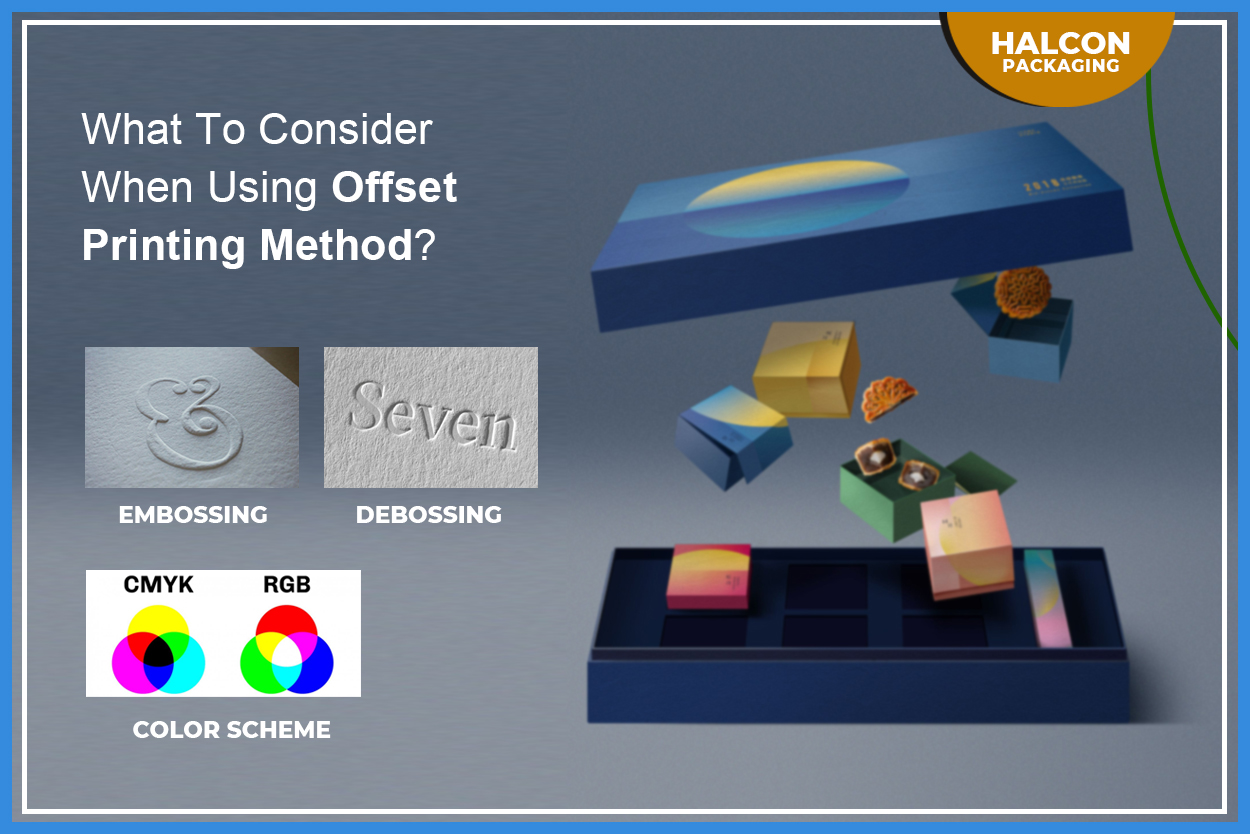

Choices In Colors Schemes:

If you want to utilize a color build on many pages inside a signature work, such as a print book, bear in mind that color variance will occur across the press sheet and, in particular, from press signature to press signature. Assume you have a backdrop area screen that will be displayed on all pages inside a portion of the book. If the signature contains other four-color pictures or heavy-coverage solid colors, your book printer may need to alter the inks on the press to maintain the photos true to color throughout the press run. If you put one page of the print book next to another, you may see a color shift inside the area screened. To avoid this problem, consider using a separate PMS ink for the backdrop instead of creating the color using process inks. Whether or not the packaging suppliers need to alter the process inks, a PMS color will remain precisely the same throughout the press run. This will cost a bit extra, but if you are currently printing on a five- or six-color press, the additional cost should be modest (perhaps a few hundred dollars). It's also money wisely spent.

Alignment of Crossovers:

Commercial printing is both an art and a science. As previously stated, there are differences in printing and finishing like embossing, Silver or Gold foiling. It is critical to realize that finishing equipment is not perfect. When you stretch type or a graphic from one page to the next in a multi-page signature work (such as a print book), the left-hand page (called the "verso") portion of the image may not line perfectly with the right-hand page (called the "recto") section of the image. There are a few solutions to this problem (or, rather, limitation of offset lithography). If you place the crossover picture in the signature's center spread (the two pages that are side by side on the press sheet), your image will be able to cross over from the left-hand page to the right-hand page without being misaligned (after all, they are side by side on the sheet, unlike all other pages in the press form).

Another option is to avoid inserting pictures that cross over diagonally from one page to the next in a signature, as well as thin lines that cross over from the left-hand to the right-hand pages. Thicker crossover pictures are more forgiving than thinner ones, and horizontal crossovers are more forgiving than diagonal crossings. (This is actually due to the limits of human sight.) And, as mentioned in the prior section, unless you use a PMS, the colors on the left-hand page will not exactly match those on the right-hand page (rather than a process color build).

Also Read: How To Buy Wholesale Cigar Boxes with Ease?

Total Surface Coverage:

Also Read: How To Buy Wholesale Cigar Boxes with Ease?

Total Surface Coverage:

If you are creating a four-color product, you should be able to specify 100 percent ink coverage for each of the process colors (cyan, magenta, yellow, and black). This is a bad idea. If you print on newspaper, you will end up with a sticky mass of paper and ink. Sheetfed printing on gloss material is a little more forgiving, but the ink will never dry fully. There is only so much ink that can lie on top of a coated press sheet or soak into the fibers of an uncoated press sheet without damaging the paper or the printing process in offset personalized packaging. 340 percent total area coverage is usually suitable for sheetfed printing on gloss or dull material (the sum of all process inks: for example c100 m80 y60 k100). For newspapers, you should reduce the overall area covered to 240 percent or less (for example, c60 m80 y20 k80). These figures are only guidelines. Inquire with your commercial printing provider about the target percentages for the paper you are using and his specific printing press. It is possible to achieve deep, rich colors on press without using a lot of ink.

Background Choices: UV Inks vs. Traditional Inks:

UV inks cure by ultraviolet light exposure, as opposed to typical printing inks, which dry through oxidation, evaporation, and/or absorption. Ultraviolet inks, in particular, are “dual-state” inks. They are liquid until they are subjected to UV radiation, at which point they stiffen immediately. Traditional UV printing inks comprise pigments as well as carriers, which are liquids in which the pigment particles are suspended: oils, resins, and solvents. When ink is printed on a press sheet in sheet-fed offset printing, the solvent enters the paper fibers (absorption), and the resin rests on top of the surface and solidifies while a chemical reaction with the environment (oxidization) occurs, finally leaving a coating of dried ink.

Traditional bespoke printing inks comprise pigments and carriers, which are liquids in which the pigment particles are suspended: oils, resins, and solvents. When ink is printed on a press sheet in sheet-fed offset printing, the solvent enters the paper fibers (absorption), and the resin rests on top of the surface and solidifies when a chemical interaction with the environment (oxidization) happens.